Low-Temperature Thermal Management System Solutions for Engineering Vehicles

Supports both front-fit and aftermarket solutions

The low-temperature thermal management system solutions for Engineering Vehicles can be customized for OEM integration to meet specific requirements, with standardized models also provided to streamline installation for aftermarket retrofit providers.

Suitable for various types of Engineering Vehicles

Yusenn provides customized thermal management solutions for all Engineering Vehicles, engineered to meet specific customer requirements. The system design prioritizes seamless integration and operational efficiency.

All categories of products are safe and reliable

The various products in the low-temperature thermal management system solutions for Engineering Vehicles are strictly controlled from design and development, experimental verification, production process to factory inspection, ensuring stable and reliable product quality.

Addressing the range anxiety and winter heating issues of new energy vehicles

New energy vehicles are affected by low temperatures in winter, resulting in reduced range, longer charging times, and lower operational efficiency. Yusenn's low-temperature thermal management system solutions effectively addresses issues such as diminished battery performance and excessive energy consumption caused by electric heating in new energy vehicles under cold winter conditions.

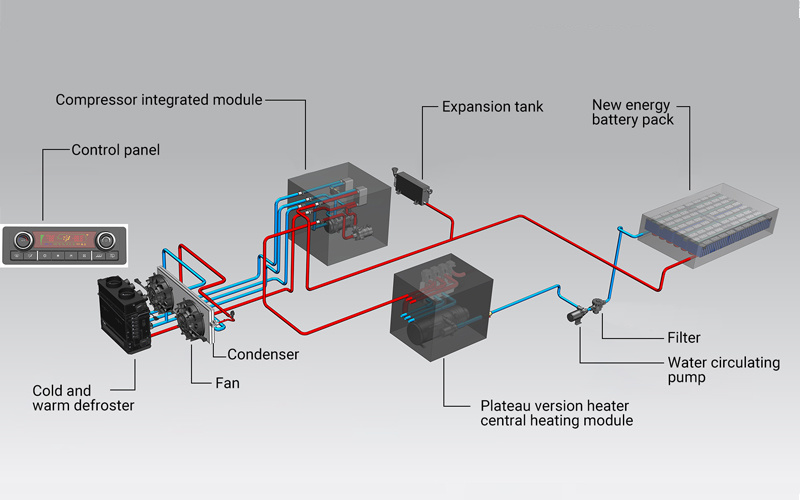

The Low-Temperature Thermal Management System Solutions for New Energy Trucks

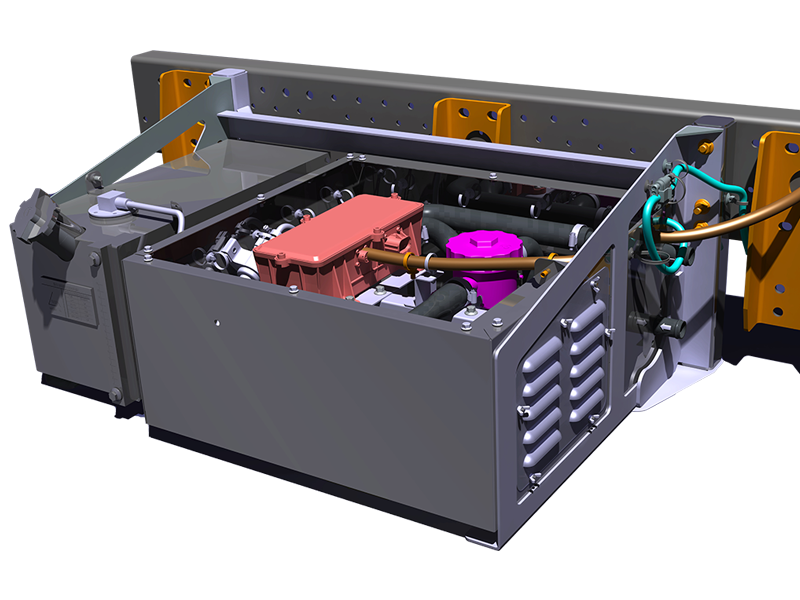

The charging and discharging of new energy truck batteries in winter are affected by low temperatures, and the battery life is greatly discounted. The integrated solution for high-cold thermal management of new energy trucks realizes the thermal management of the whole vehicle through the cooperation of the central heating modules, defrosting and condensers of the plateau heater to achieve thermal management of the whole vehicle, which can realize the insulation, defrosting and defogging of the new energy battery pack and the heating of the whole vehicle.

The low-temperature thermal management system of new energy trucks 2.0 "oil-electric dual power" can quickly insulate the battery pack of new energy trucks and continuously heat the cabin indoors, so as to achieve heating without electricity, allowing new energy trucks to bid farewell to the anxiety of battery life, and can also travel freely and operate efficiently in winter.

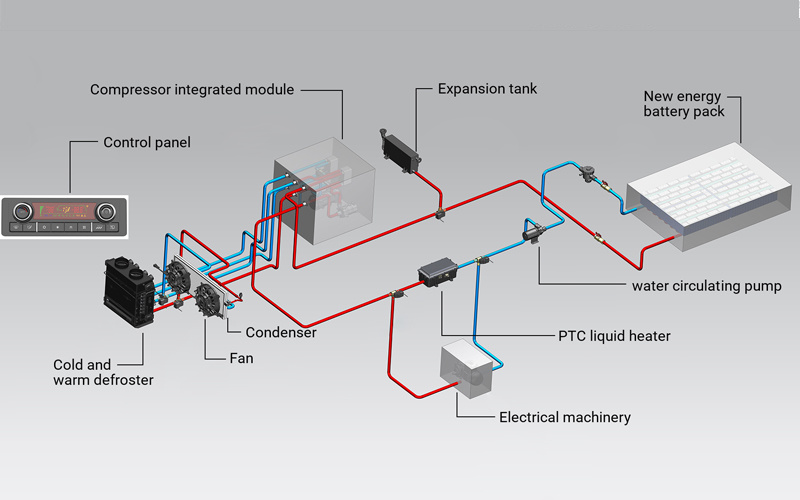

Integrated Thermal Management Solution for Waste Heat Utilization in New Energy Truck Motors

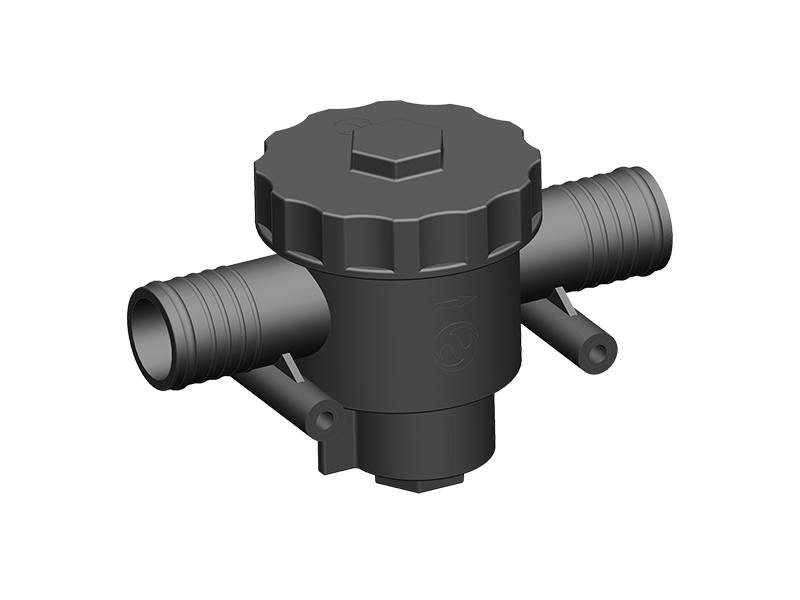

The motors in new energy trucks generate a significant amount of heat that requires dissipation. By harnessing the motor's waste heat in parallel with a PTC electric heater and regulating the system through a water valve actuator, this solution enables thermal insulation for the new energy battery pack and provides cabin heating for the entire vehicle.

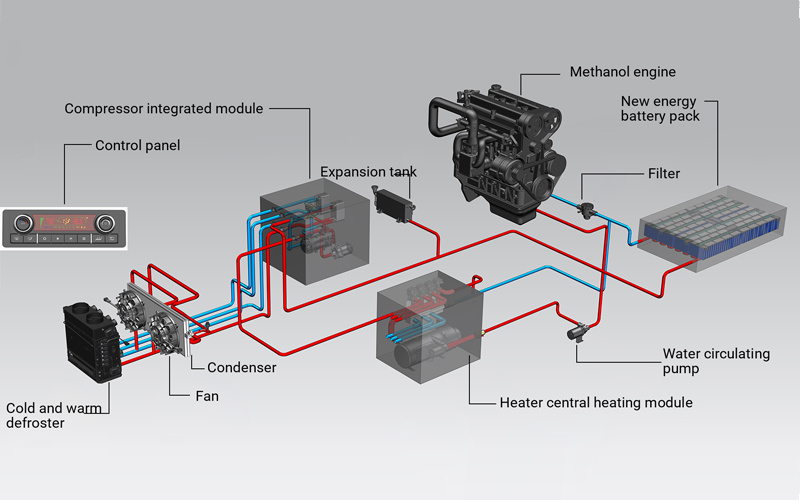

The low-temperature thermal management system solutions for Methanol (Hydrogen Fuel) New Energy Trucks

The methanol (hydrogen fuel) new energy truck can achieve insulation of the methanol (hydrogen fuel) new energy truck battery pack, preheating of the methanol engine, and heating of the entire vehicle through the methanol heater centralized heating module, cooling and heating defroster, filter, water pump and other accessories.

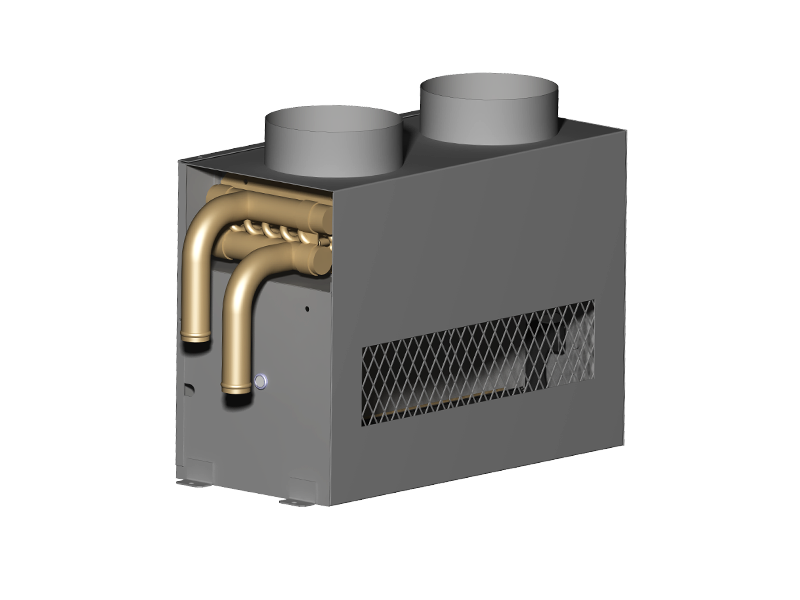

Fuel engineering vehicle thermal management solution-independent heating system

Engineering Vehicles face extended preheating periods in frigid winters, requiring an additional 10-20 minutes of waiting after engine startup before cabin heating becomes available. Once the Engineering Vehicles is shut off, these vehicles lose access to engine-generated heat.

Air-Type Parking Heating System:This standalone heating system operates independently of the vehicle’s original setup. It enables rapid cabin warming without starting the engine—simply activating the parking heater delivers immediate heat, eliminating waiting times.

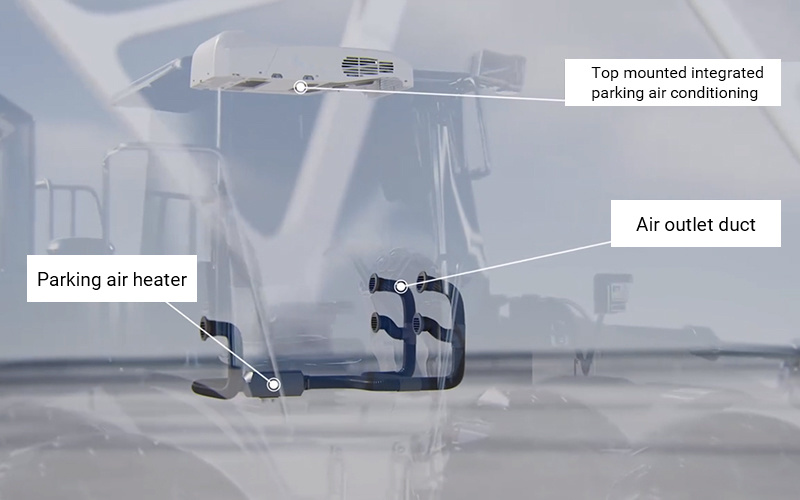

Overhead Integrated Parking Air Conditioning System:Separate from the vehicle’s main cooling system, this roof-mounted unit provides refrigeration even when the engine is off. During rest periods, operators can use the parking AC to cool the cabin, avoiding prolonged engine idling and preventing mechanical wear.

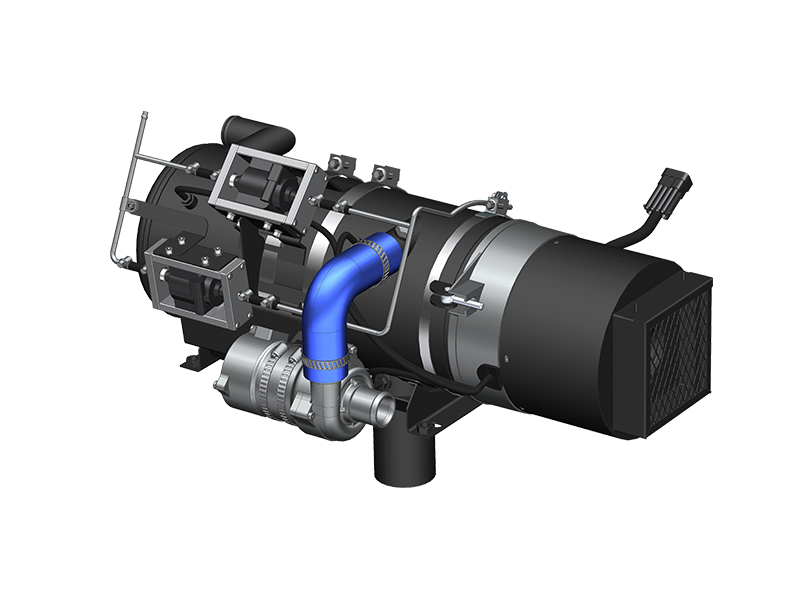

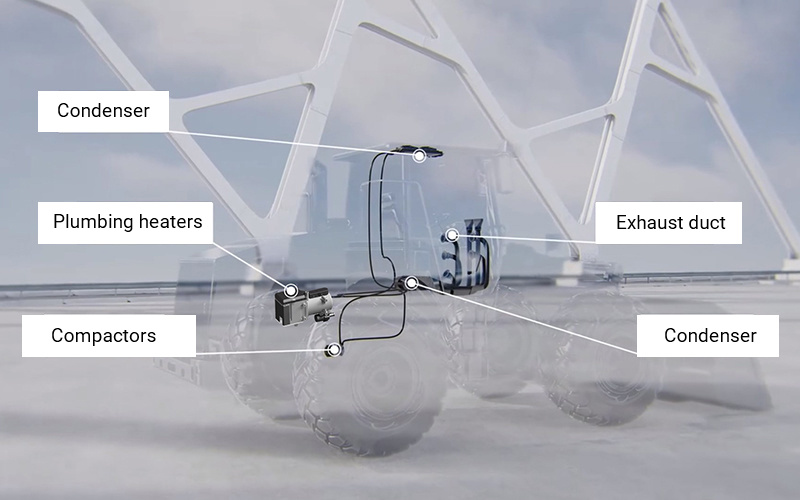

Fuel engineering vehicle thermal management solution - independent plumbing heating system

In cold winters, heavy-duty fuel-powered trucks often face issues such as failure to start or frozen fuel tanks. Installing a liquid-fueled parking heater and configuring it with appropriate piping systems can effectively resolve these problems.

For fuel-powered trucks, equipping a Fuel Water Parking Heater enables:

Pre-warming the engine in advance (ensuring smoother cold starts);

Quick defrosting of windshield ice upon entering the vehicle;

Immediate warm air supply to the cab for driver comfort.

Provide technical requirements and obtain solutions

Please leave your email, our professional person will contact you asap!